Over 20 Years of Strict Quality Control

Annual HDPE Sheet Production (tons)

Factory Floor Space (m²)

Advanced Production Lines (units)

SANYOU PLASTIC is a premier HDPE sheet manufacturer in China, offering comprehensive solutions including mono/dual-color extrusion, precision cutting, and custom fabrication. We deliver cost-effective standard and custom HDPE sheets with exceptional durability and chemical resistance. Our products serve construction, food processing, and industrial sectors, maintaining reliable performance even in demanding environments.

We supply various sizes and colors of HDPE sheets at competitive prices.

Standard dimensions : 1.22×2.44m / 2x3m

Custom size options available.

We provide HDPE sheets in different colors to meet the needs of different industries and applications.

Excellent UV resistance and durability, ideal for outdoor construction, marine applications, and chemical storage tanks.

Hygienic and clean appearance, perfect for food processing equipment, medical applications, and sanitary environments.

High visibility for safety, ideal for warning signs, safety equipment, and hazard identification markers.

Due to its bright color design, it is mainly used in outdoor playground equipment, warning signs, etc.

We offer HDPE sheets in different thicknesses ranging from 2mm to 25mm to meet a variety of industrial and commercial needs. We also offer custom thicknesses to meet your specific project needs.

Best for lining, covering, and applications requiring flexibility.

Ideal for structural applications and moderate loads.

Perfect for high-impact, heavy-load industrial applications.

We provide HDPE sheets in different colors to meet the needs of different industries and applications.

Characteristics:Uniform, non-porous surface, easy to clean and maintain

Ideal Applications: Food processing equipment and countertops,laboratory tables and equipment

Characteristics: Hides minor scratches and imperfections

Ideal Applications:Industrial work surfaces, material handling equipment, marine applications (boat components)

Characteristics:Highly textured, diamond-pattern or raised stud surface

Ideal Applications: safety platforms and catwalks, industrial flooring and platforms, marine decking and dock surfaces.

Our HDPE sheets are available in a variety of standard grades, including natural, recycled, UV resistant and marine grade options, each designed to meet specific industrial needs. We also support special custom grades, ensuring tailored solutions for unique project requirements.

Advantage: Excellent purity and chemical resistance with high impact strength.

Best for: Food processing equipment, pharmaceutical applications, and potable water systems.

Advantage: Superior weather resistance that prevents degradation from sun exposure.

Best for: Outdoor signage, marine docks, agricultural equipment, and exterior construction.

Advantage:Save energy and resources.

Best for: drainage ditches and structural materials.

HDPE sheets are widely used in many industries

High density and toughness make them durable, low in water absorption, and easy to maintain.

Made from high-density polyethylene (HDPE), they are resistant to rotting and often feature various anti-slip textures for added safety.

It can withstand high-speed impact and is not easy to break, effectively reducing the damage to the protective device caused by the kart.

Self-lubricating, smooth gliding of the curling stones; no energy required for ice making, low operating costs; environmentally friendly, pollution-free, and low noise.

We use advanced production technology to ensure stable and reliable product quality

Select high-quality HDPE raw materials to ensure stable material performance

Match colors according to customer needs and add necessary additives

Use advanced extrusion equipment to precisely control the thickness of the sheet

Multi-stage cooling system ensures the plate is flat and not deformed

Precise cutting and professional packaging to ensure safe transportation

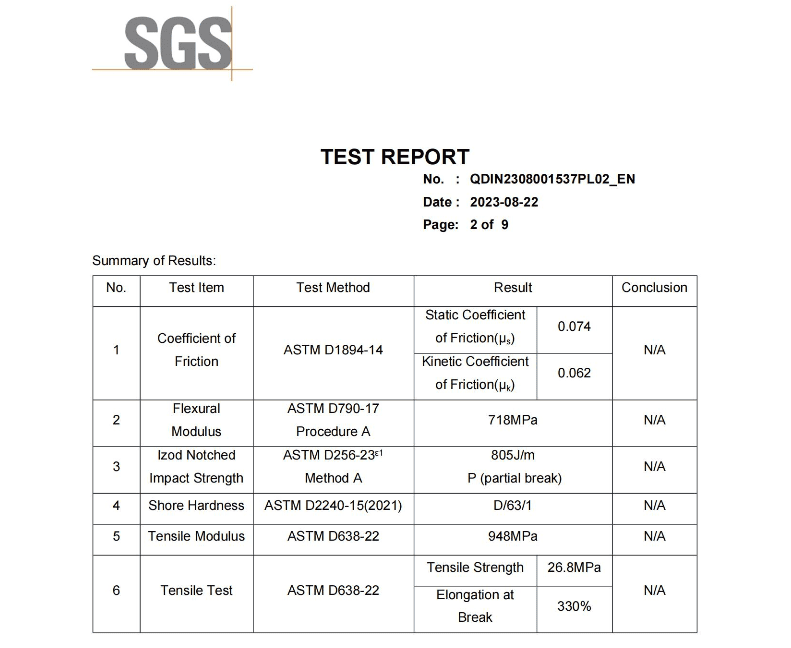

To guarantee the quality and performance of our HDPE sheets, we collaborate with renowned third-party testing agencies to provide comprehensive testing and certification, ensuring full transparency and reliability for our clients.

Our products have passed ISO9001 quality management system certification and comply with SGS testing standards, CE standards and other international certifications.

Physical Performance Testing: Independent verification of key physical properties such as impact strength, tensile strength, and hardness. These tests ensure that our HDPE sheets meet industry standards for durability and toughness in demanding applications.

Chemical Resistance Testing: Our HDPE sheets are tested for resistance to chemicals, including acids, alkalis, and solvents. These tests confirm the material’s ability to maintain performance and integrity in harsh chemical environments.

Available Upon Request: Complete third-party testing reports covering both physical and chemical performance are available to customers upon request, offering full transparency and confidence in our product quality.

Send Your Inquiry Now

Over 20 Years of Strict Quality Control

Cooperating customers come from more than 80 countries

Customer Satisfaction

FAQs about HDPE sheets

HDPE sheet has excellent chemical resistance, high impact strength, low water absorption, easy processing, environmental protection and non-toxicity. It can maintain good performance in the temperature range of -50°C to +80°C and is suitable for a variety of harsh environments.

We provide HDPE sheets with different thicknesses from 3mm to 50mm. Common thicknesses include 3mm, 5mm, 8mm, 10mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, etc. Special thicknesses can be customized according to customer needs.

Yes, we can customize HDPE sheets in different colors according to customer needs. Common colors include black, white, blue, green, yellow, etc. Special colors can also be prepared on request.

HDPE sheets can be processed by cutting, drilling, milling, thermoforming, welding, etc. We can also customize processing according to the drawings provided by customers.

Yes, we can provide free samples to potential customers. Please submit your sample request using the contact form at the bottom of the page, and our sales team will contact you shortly.