Ultra-High Molecular Weight Polyethylene (UHMWPE) has a molecular weight 10x higher than standard polyethylene, this engineering polymer delivers extraordinary properties that traditional metals and plastics can’t match. By 2027, the global UHMWPE market is projected to reach $2.8 billion , driven by its unique advantages in demanding applications.

1. Extreme Wear Resistance: The 10X Advantage

UHMWPE’s most celebrated property is its incredible abrasion resistance. Laboratory data reveals:

case: A Colombia copper mine replaced steel conveyor liners with 20mm UHMWPE sheets, reducing replacement frequency from every 3 months to 2.5 years – saving $300,000 annually.

2.Frictionless Performance: Self-Lubricating Marvel

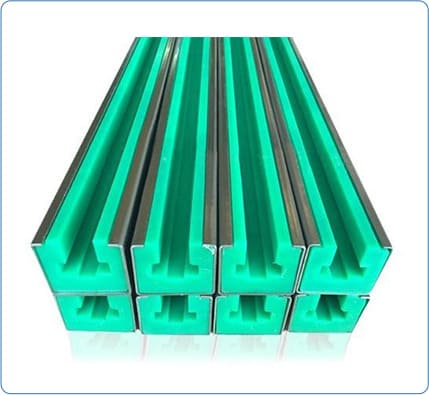

The material’s exceptionally low coefficient of friction (just 15% of steel) enables:

“Switching to UHMWPE guide rails eliminated our need for grease in bottling lines, cutting maintenance hours by 70%.” – Plant Manager, a well-known beverage company.

3. Sustainability Edge: Eco-Efficient Engineering

UHMWPE supports circular economy goals through:

Case : A Sri Lankan customer used UHMWPE marine fender pad to solve the problem of seawater corrosion and UV radiation

As industries seek lighter, stronger, and more sustainable materials, UHMWPE sheets are becoming the cornerstone of innovation. With recent developments like conductive UHMWPE for EV batteries and radiation-shielding grades for nuclear plants, this material continues to break performance barriers.

UHMWPE isn’t just another plastic – it’s the most cost-efficient insurance against downtime you can buy.

Request a free sample kit or download our engineering guide to explore UHMWPE solutions for your industry.