Introduction: The Evolution of Conveyor Roller Technology

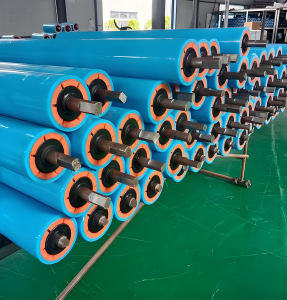

In the world of industrial conveying systems, idler rollers play a critical role in maintaining efficiency, reducing energy consumption, and ensuring smooth material handling. While traditional materials like steel, nylon, and HDPE have dominated the market for decades, Ultra-High Molecular Weight Polyethylene (UPE) has emerged as a superior alternative that addresses many limitations of conventional rollers. UPE idler rollers represent a significant technological advancement in bulk material handling, offering exceptional durability, reduced maintenance, and improved operational efficiency across various industries including mining, agriculture, and manufacturing.

The transition to UPE rollers isn’t merely a material substitution—it’s a comprehensive upgrade that delivers tangible benefits in performance, cost savings, and system reliability.

Abrasion Resistance and Extended Service Life

The most significant advantage of UPE idler rollers lies in their extraordinary abrasion resistance, which far exceeds that of traditional roller materials. Laboratory tests and field applications consistently demonstrate that UPE rollers last 5-8 times longer than standard nylon or steel rollers in high-abrasion environments. This exceptional durability stems from UPE’s unique molecular structure, characterized by extremely long polymer chains that create a tough, impact-resistant material with outstanding wear properties.

In practical terms, this extended service life translates to substantial operational benefits. Operations dealing with abrasive materials such as mined ores, gravel, sand, or recycled materials experience significantly reduced roller replacement frequency. Where traditional rollers might require replacement every 6-12 months in demanding applications, UPE rollers can often perform effectively for 3-5 years before needing replacement. This longevity not only reduces direct replacement costs but also minimizes system downtime for maintenance, leading to improved overall equipment effectiveness (OEE).

Superior Corrosion Resistance and Chemical Inertness

Beyond abrasion resistance, UPE conveyor rollers offer exceptional corrosion resistance that makes them ideal for harsh operating environments. Unlike steel rollers that are vulnerable to rust and corrosion, particularly in wet or chemically aggressive environments, UPE remains completely unaffected by moisture, most chemicals, and environmental factors that rapidly degrade alternative materials.

This chemical inertness provides particular advantages in industries such as chemical processing, mining (where water is used for dust suppression), food processing, and wastewater treatment. UPE rollers resist attack from acids, alkalis, and solvents that would quickly compromise the integrity of metal or even some polymer rollers. This resistance eliminates concerns about roller degradation contaminating materials being conveyed, making UPE rollers particularly valuable in industries with strict purity requirements.

Significant Energy Efficiency and Noise Reduction

Noise reduction represents another significant operational advantage. UPE rollers operate much more quietly than metal alternatives, generating noise levels 10-15 decibels lower than comparable steel roller systems. This noise reduction creates a safer, more comfortable working environment, helping operations comply with occupational health and safety regulations regarding workplace noise exposure while improving employee satisfaction and productivity.

Reduced Maintenance Requirements and Operational Costs

The maintenance advantages of UPE conveyor rollers contribute significantly to their total cost of ownership benefits. The combination of exceptional wear resistance, corrosion immunity, and self-lubricating properties eliminates multiple maintenance tasks associated with traditional rollers. Operations can eliminate routine lubrication entirely, as UPE requires no periodic greasing to maintain optimal performance.

The installation and replacement process for UPE rollers is notably simpler and safer than for heavier alternatives. Weighing a fraction of comparable steel rollers, UPE rollers can typically be installed by a single technician without requiring mechanical lifting equipment. This weight reduction not only speeds up maintenance procedures but also reduces the risk of workplace injuries associated with handling heavy components.

Enhanced Performance in Specialized Applications

The unique properties of UPE idler rollers make them particularly valuable in specialized applications where traditional materials fall short. In food processing and pharmaceutical applications, UPE’s FDA-compliance and non-contaminating properties make it ideal for direct contact with edible products. The material’s natural lubricity and non-stick characteristics prevent material buildup that could harbor bacteria, supporting improved hygiene standards.

The temperature resistance of UPE (typically from -250°F to +180°F/-157°C to +82°C) further expands its application range. While not suitable for extremely high-temperature applications where ceramic or specialized steel rollers might be required, UPE performs excellently across the temperature range encountered in most industrial environments, maintaining its mechanical properties and dimensional stability through seasonal variations.

Conclusion

The advantages of UPE idler rollers extend far beyond simple material superiority to encompass operational efficiency, cost reduction, and improved system reliability. While the initial investment in UPE rollers may be higher than conventional options, the total cost of ownership—factoring in extended service life, reduced energy consumption, and minimized maintenance requirements—typically demonstrates a compelling return on investment within the first 12-18 months of operation.